| 2019.09.20 |

| Since the 300 hit 300k miles last month, some electrical gremlins are starting to rear their ugly heads. It all started a couple of weeks ago with a flashing tire pressure warning lamp on the dash. I had replaced the wheel sensors earlier this year when I purchased new tires, and managed to go several months without issue, so it's safe to say that wheel sensors are not the problem. A little research turned up that a solid lamp means low pressure condition and a flashing lamp indicates a system error. I pulled out my Starscan and it reported a CT1504 DTC. Basically sensor 4 getting incomplete message. Two things of note: it's never a good sign when the dealer service manual says "The conditions necessary to set this DTC are not present at this time.", and that the car only has three sensors (though error conditions for 5 exists). One in the front and a two receivers in the rear. Idea being that if error wasn't reported in the either of the three, it has to be the forth, process of elimination as a cost savings. Until I get some time to dig into it, I can live with the twice daily blinking for 30 seconds at a time. Now notice that I had said "gremlins", plural. Earlier this week as I'm backing out of the driveway, I turned on the cabin lights to wave goodbye to my lovely wife. I used the dimmer control (set to max to activate interior lights) to do this. As I did this, it seemed to have triggered a dash lamp test, as every single lamp on the dash lit up for about 10 seconds. Unfortunately, I can't replicate how this happened. As a bonus, later the same day, the airbag warning and passenger airbag off lights came on for about a minute. I guess I'm spending this weekend with the Starscan. I'm hoping this doesn't mean a bigger issue down the road. |

| 2019.08.12 |

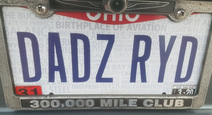

The 300 finally hit 300k miles this past Tuesday. It's been just a couple weeks shy of 5 years since the 200k mark. To celebrate (I use term loosely), I spent this weekend doing the required 100k mile tune up, which includes new plugs, front/rear differential fluid drain/fill, transmission drain/fill/filter replace, and EGR valve replacement. In addition, it also was time for oil change, tire rotation, and other general maintenance. Top everything off with a car wash. Needless to say, I spent just almost the entire weekend in the garage.

Now I did say almost. A couple of months ago, the wife and girl cornered me and asked about doing a 5k walk/run. My immediate reaction is "hard pass", but they said donuts were going to be available, so that piqued my interest, but still wasn't that interested (I mean, come on, get up *early* on Sunday morning to walk over 3 miles... for donuts?). After some badgering, I end up getting up early yesterday to walk over 3 miles for a grand total of 4 donuts.

|

| 2019.07.16 |

| Even though I haven't updated in a while, it doesn't mean I haven't been busy. Au Contraire! I've been sitting on an old traffic light for over 20 years that was a present from my in-laws. It was a little rough around the edges, but complete. Shortly after getting it, I had broken it down and tried to strip the old paint off (tried chemical and sanding) without success so it sat in the corner of the basement. Fast forward 20 years, the wife and I were going through stuff in the basement and she asked me if I planned on doing anything with it. I have a garage now, so it was time to get it repainted and working again. Normally, I'd write up a project page for this, but I didn't take any pictures of the process and honestly, there wasn't much too it. I had a local guy sand blast the fixture, then I primed and painted it yellow. For the light switching (keep in mind that this was controlled remotely), I opted for an Arduino Uno and a SainSmart 4 channel relay switch board. A simple Arduino sketch loop to cycle the lights and voila, a working traffic light. Cost of the two boards was under $20, so this was a no brainer. I realize that the Uno is overkill for just blinking lights, but it does give me options in the future, say like controlling the traffic light with the garage door (eg. red = door closed, yellow = opening/closing, green = open), or even parking position.

|

| 2019.05.24 |

| I had taken a couple of days off to make a four day weekend. I spent the day Saturday doing yard work/misc chores and Sunday working on the 300s AC (which didn't get very far). I spent Monday with my daughter shopping and spending the day downtown by the river (The Banks). We finally had a chance to check out the electric scooters (Bird). We had a blast! I spent Tuesday with my wife at Kings Island. While we had an awesome time, it seemed since Cedar Fair had taken over, some the rides are showing neglect (Viking, Monster, Shake/Rattle/Roll, Racer). However, it was nice to see the return of the old fashion cars though. While doing all that, I was also able to get the 300s AC compressor replaced and charged this past weekend, but it was a tumultuous journey. I had a local Firestone Complete Auto Care evacuate the system on Sunday. It took all of about 40 minutes and costs 30 bucks to do, so easy deal there. From there, it was a bit of work. Hardest part was getting the old compressor out and the new one installed. It didn't help that the water coolant return line and thermostat sit right over the compressor, so I had to pull that, plug it, and clean up the resulting mess. Then, I had to pull the cooling fan to make room for the compressor to come out, which in turn, meant that the upper coolant hose had to be pulled, resulting in again, more mess. From there, it got a little more frustrating. A combination of bad unit location and complete lack of arm above head stamina made getting the new unit bolted in a chore from hell. That alone took a lot longer than I care to talk about. I had used my buddy's gauge set for the initial vacuum test, but had an issue with the set (unlabeled knobs, couldn't tell if they were open or closed). I ended up running out to Harbor Freight and getting a new gauge set Monday. Ran another vacuum test over night. Came in the next morning (Tuesday) to find no vacuum at all which indicates a leak. After cussing a bit, it occurred to me that I didn't lubricate the gaskets on the new gauge set. Put yet another vacuum on the system and came back 6 hours later, no vacuum loss, yay! Getting the refrigerant back in the system took a bit longer than I expected. The issue was getting the compressor to engage. There is a pressure switch in the line that will keep the compressor from engaging with either low or high pressure. Normally, you can just short the sensor to force the compressor on, but the 300 had a 3 wire sensor, so after some tries, I found that unplugging/plugging the sensor in did the trick. Tedious, but I eventually got it. Since the install, we've been in the upper 80s with high humidity, and I'm rolling like a freezer truck. One other surprise during the install: I had ordered a pre-oiled compressor for the single reason of not having to put oil into the system when putting in the refrigerant. First line in the instructions is to drain/dispose of the oil and refill 75ml into the compressor and put 75ml into the system, which is a royal PITA. Naturally didn't realize this until I was knee deep in the install. Finally, a shout-out to the ChrisFix Youtube channel. This video was immensely helpful on charging the system. |

| 2019.05.15 |

| As the 300 is clawing it's way to 300k miles (at 294k as of this post), repairs/maintenance costs are starting to add up. Outside of the 100k mile service (spark plugs, transmission/diff service), I'm about due for new shocks/struts, and the A/C system is starting to act up. By act up, I mean it was actually blowing snow inside my car the other day. It doesn't help that I have the A/C turned on year round, so it shouldn't be a surprise after 13 years it's time for some attention. After some research, I decided to try to tackle this myself. If I only have to replace the compressor, it should be fairly painless. If the problem is system wide, requiring the dashboard to be pulled, it gets painful real quick. By most accounts, pulling the dashboard takes approx 4 hours to pull and 4 hours to put back in. Anyways, I borrowed a gauge set from a buddy and picked up a vacuum pump from Harbor Freight. I'll do some initial diagnostics before having the refrigerant evacuated. This should be an interesting learning experience to say the least. |

|

©2004-2020 Paul Boehmer |